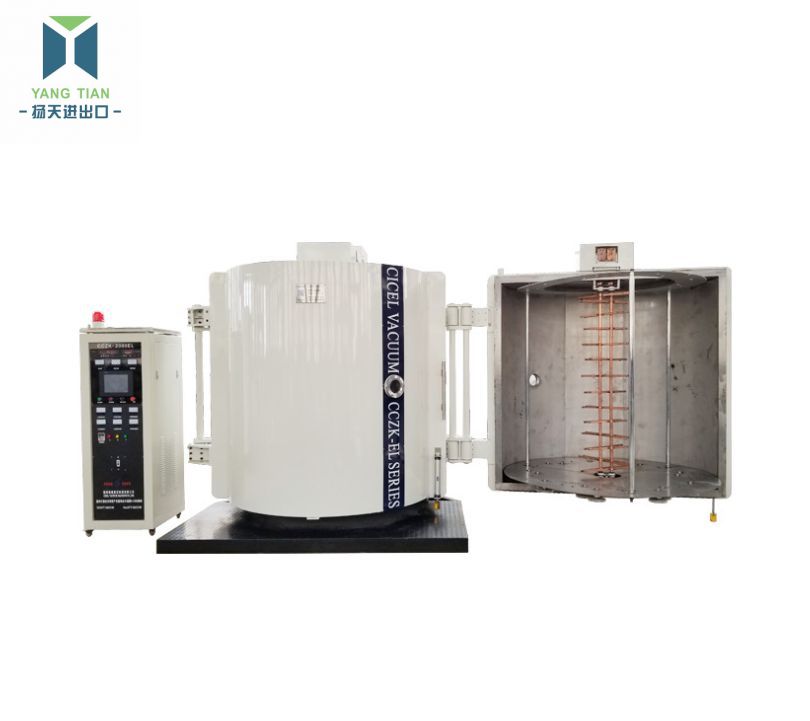

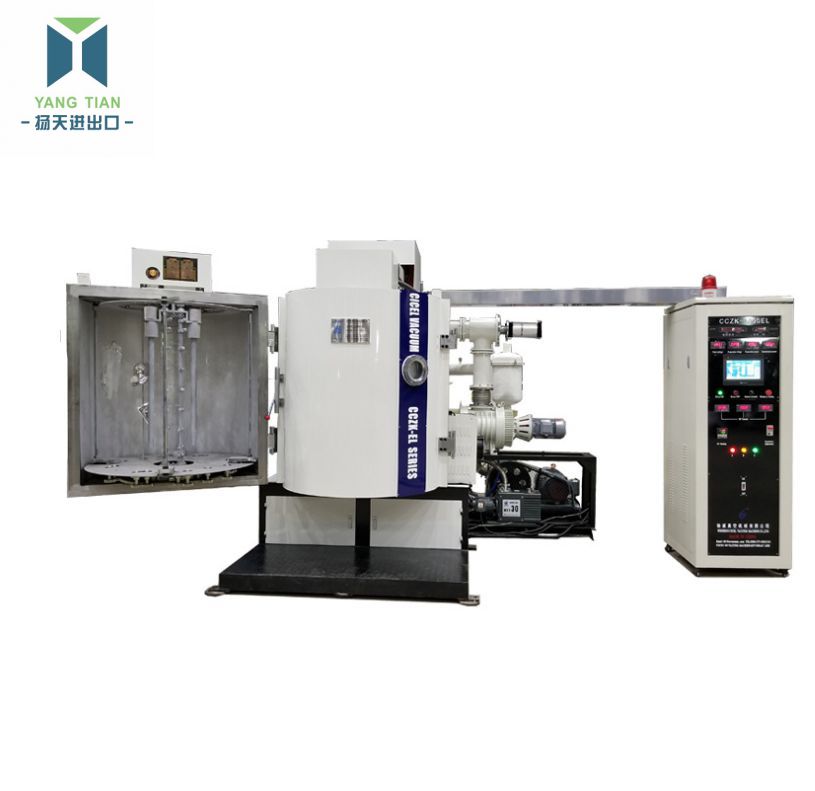

Product Display

Product Introduction

Main products:

Evaporative single vacuum coating machine.

Evaporative double vacuum coating machine (power saving 30%).

Acrylic magnetron coating production line.

Plastic vacuum coating machine.

Glass cleaning machine, glass painting machine.

Glass painting machine.

PVD multi-arc ion plating machine.

Optical coating machine.

A complete production line of high-grade automobile rearview mirrors.

Large magnetron coating production line

The company specializes in exporting vacuum coating equipment and vacuum technology research, the leading domestic development and production application of high-tech equipment manufacturing enterprises, in vacuum coating technology: evaporation coating technology and magnetron coating technology has reached the advanced level at home and abroad, and has successfully developed and produced evaporation coating machine, coating production line, medium frequency magnetic control coating machine and high-grade silver mirror production line.

Successfully completed the large-scale coating production line.

Our products have also obtained a number of national patents, in strict accordance with the guidelines of the ***:2000 quality management system, the courage to innovate.

Strong technical force, strong production capacity, complete processing equipment, with a group of experienced technical designers and production and sales staff, tailored for customers affordable products and satisfactory after-sales service.

And can provide customers with overall solutions, over the years, there are a large number of fixed customer groups at home and abroad.

The evaporative vacuum coating machine uses resistance heating to atomize the wire (aluminum, copper, titanium) in the vacuum environment. After atomization, molecules are deposited on the surface of glass, acrylic and plastic to form a metallized reflector.

Ideal equipment for gold plating and branding.

UV coating process of vacuum coating machine.

Evaporation coating equipment aluminizes the plastic surface through PVD technology, which can metallize the plastic surface and then spray various colors, which needs to be treated by UV before and after. The following is the process and parameters of UV coating production process:

|

企业特殊行业经营资质信息公示

企业特殊行业经营资质信息公示